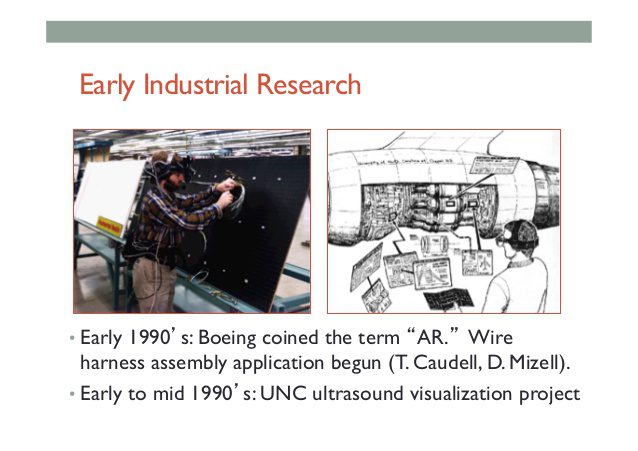

Augmented Reality: Boeing Used AR Building Planes in the 1990s

Here is a brief review of the history of Augmented Reality (AR), in this post, you will learn about how Augmented Reality: Boeing Used AR Building Planes in the 1990’s.

Boeing is a major maker of aircraft in the world today. In this presentation we will revisit some manufacturing problems that the company had to overcome. Aircraft are complex in manufacturing the components and the company needed their people to process large amounts of data in their roles. CAD systems were used to process and store engineering designs.

Augmented Reality was accessed through a heads-up display combined with headset position sensing and workplace systems. Furthermore, tracking volumes are application dependent to drill rivet holes using to span the gaps requirements, with two or more tracking technologies spanning the extremes.

HUDset Technologies

Heads-up display technology had been used for over 20 years with the traditional application being fighter pilot displays. The basic elements include an image source, relay optics, and a beamsplitter.

Moreover, in 1985 Warren Robinett and his colleagues from University of North Carolina built a see-through display and this design led to many different uses in the operations.

Applications Tasks included

Connector Assembly

Electronic Panel Assembly

Maintenance

Kevlar Duct Layup

Mandrel Measurement

Formboard

Structural Riveting

There are many complexities and processes involved in manufacturing an aircraft. Measurement templates, diagrams, and marking devices to display over information on pieces are part of that complexity.

The company claimed an immediate result at the time, utilizing systems driven by standard inexpensive microprocessors and the applications were possible. For further information you the reference source is listed below.

Source: Augmented Reality: An Application of Heads-Up Display Technology to Manual Manufacturing Processes

THOMAS P. CAUDELL. AND DAVID W.M IZELL